kekon

Full Member level 3

- Joined

- Sep 19, 2002

- Messages

- 155

- Helped

- 5

- Reputation

- 10

- Reaction score

- 3

- Trophy points

- 1,298

- Location

- Poland, Białystok

- Activity points

- 1,493

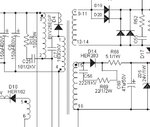

I've built several off-line forward converters so far. However i always face the problem how duty cycle depends on connected load. Most of my designs use two transistor topology so theoretical maximum duty cycle is limited to 50% (in practice i always use about 40..45%).

For example, a 320W forward converter (80V, 4A) has 43% duty cycle at lowest input voltage and full load. When 2A is drawn (half load) the duty cycle in not 2x lower (about 21 %) but it stays at about 35% so it seems that duty cycle relationship vs load is not linear. I want to find mathematical formula to calculate it. Did someone of you have similar problem ?

For example, a 320W forward converter (80V, 4A) has 43% duty cycle at lowest input voltage and full load. When 2A is drawn (half load) the duty cycle in not 2x lower (about 21 %) but it stays at about 35% so it seems that duty cycle relationship vs load is not linear. I want to find mathematical formula to calculate it. Did someone of you have similar problem ?

Last edited: