mrinalmani

Advanced Member level 1

- Joined

- Oct 7, 2011

- Messages

- 467

- Helped

- 60

- Reputation

- 121

- Reaction score

- 59

- Trophy points

- 1,318

- Location

- Delhi, India

- Activity points

- 5,351

Since electrolytic capacitors are not meant to be frequently charged and discharged, each ripple wave is equivalent to partial charge/discharge. To ensure long term reliability...

Where do you see this specification? Sounds like an erroneous believe to me.The electrolytic version have their life limited to generally 10K cycles.

If you have a lifetime limitation, then you should find the information in the relating datasheets.The electrolytic version have their life limited to generally 10K cycles.

lf the application is a circuit that has large fluctuations in voltage, such as a power supply for an AC servo amplifier or an inverter, select a QS,QR series capacitor that allows rapid charging and discharging. QS,QR series capacitors empIoy a special structure to increase their durability against rapid charging and discharging.

3.1.2 Operating voltage Vop

The capacitors can be operated continuously at full rated voltage (including superimposed AC voltage) within the entire operating temperature range. The permissible voltage range for continuous operation lies between the rated voltage and 0 V.

3.1.5 Superimposed AC, ripple voltage

A superimposed alternating voltage, or ripple voltage, may be applied to aluminum electrolytic capacitors, provided that:

- the sum of the direct voltage and superimposed alternating voltage does not exceed the rated voltage, and

- the rated ripple current is not exceeded (refer to chapter "General technical information, 4 Ripple current considerations") and that no polarity reversal will occur.

3.2.6 Charge-discharge proof

Frequent charging/discharging cycles may lead to a decrease in capacitance. Due to their special design aluminum electrolytic capacitors produced by EPCOS are charge-discharge proof. This means that 10e6 switching cycles will cause a capacitance reduction of less than 10% (Charge-discharge test to IEC 60384-4).

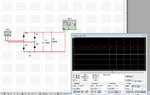

I am attaching the schematic with the oscilloscope output.

The question is how much ripple in voltage is acceptable.

Since electrolytic capacitors are not meant to be frequently charged and discharged, each ripple wave is equivalent to partial charge/discharge. To ensure long term reliability, what should be a rough accepted value of discharge percentage?View attachment 118941

The datasheets say that there is a decrease in capacitance. Did you check capacitance before and after the test?But nothing happened

We use cookies and similar technologies for the following purposes:

Do you accept cookies and these technologies?

We use cookies and similar technologies for the following purposes:

Do you accept cookies and these technologies?