Vermes

Advanced Member level 4

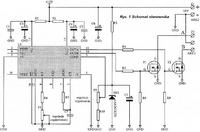

It is a mini-drilling/grinding/milling machine controller for precision operations. Such a device can be used either for cutting or drilling in PCB and other works. By adjusting the filling, the controller controls the operation of the DC motor. The operating frequency was initially set to about 53Hz, but changed to 1800Hz, because the motor operates better at that frequency. Powering system from a printer was used as the power supply. Control system was made of modified kit NE K-450 (suitable for the use with a voltage greater than 12V). Maximum power is 25W. Output voltage is 18V DC. The system allows smooth regulation of the motor rotations without loss of torque which means higher performance of the device while reducing the motor rotation speed). Regulation can be used for operations that require greater precision, such as grinding (motor runs at slightly lower rpm, but when you sand something bigger, give the full house and the grinding stone operates very efficiently).

Housing was made of aluminum profiles. Internal (with mounted power supply and controller boards), front and rear pannel were made of digested laminate. Everything was cut manually with limit of error 0,5mm.

The controller operates in the range from 0, what means that the motor can be stopped by regulation, because of the possibility of connecting other DC motors to this controller.

Link to original thread (useful attachment) – Regulator obrotów silnika DC z zasilaczem w moim wykonaniu