vitess21

Newbie level 4

Hi

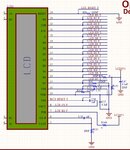

Using an existing LCD sample as reference, I have sourced out for competitor design of a similar LCD from another supplier to save on cost. When the competitor samples finally arrived, the LCD would not turn on. All voltages match however I notice a difference in segment mapping. Please see attachment.

My question is, if the pin mapping is off by one segment would that be enough for the LCD to not turn on? I would still expect to something on the LCD. Please help. Thank you.

LCD Specs

Driver: ST7036

Interface:6800 Series

Using an existing LCD sample as reference, I have sourced out for competitor design of a similar LCD from another supplier to save on cost. When the competitor samples finally arrived, the LCD would not turn on. All voltages match however I notice a difference in segment mapping. Please see attachment.

My question is, if the pin mapping is off by one segment would that be enough for the LCD to not turn on? I would still expect to something on the LCD. Please help. Thank you.

LCD Specs

Driver: ST7036

Interface:6800 Series