Vermes

Advanced Member level 4

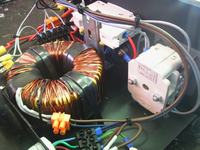

It is a useful car rectifier in a housing of an old industrial temperature regulator. 3x12V 300W transformer was used in this project.

The construction is very simple, so you do not need to have any instructions nor training, and possible faults are easy to be detected. Front panel has an ammeter, voltmeter, charging current selector switch, power switch and DC side fuse (type „S”, B16).

Heat sink of the rectifier bridge, safety fuse of the primary side of the transformer and power cord can be seen in the back of the device. Unused holes are the remains of the controlled mentioned before. There is also a kind of nameplate there.

It is good to avoid the solder joints inside the device, as they are less resistant to shocks and more difficult to be repaired in the terrain.

You can wind the secondary side of the transformer yourself to gain 3x 15V. After rectifying it is 13,3V, there is no drop while charging. The charging current increases and connects further taps of the transformer to the bridge via the switch.

The transformer is wrapped in strips of semi-vulcanizing rubber tape to prevent damage of the enamel on the winding wire during transport.

Elements used:

- housing

- transformer

- more than 15m of winding wire 1,1mm2

- 50A rectifier bridge

- heat sink of the bridge

- charging current switch

- ammeter

- voltmeter

- automatic fuse

- main power switch

- glands

- clamps

- black and brick matt spray

- individual cables, the ends of the cables, screws, nuts and hose

Link to original thread (useful attachment) – Prostownik samochodowy 12V/15A