eem2am

Banned

Hello,

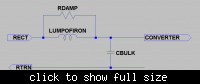

We are currently designing an offline Power Factor Corrected Flyback for 53W of maximum output power.

This is for a temperature controlled , two outlet shower (head and body jets). The hot and cold water flow is controller by stepper motor valves.

(total 4 stepper motors).

Everything on the secondary side is an isolated load.

The loads are:

4 stepper motors (10W each)

80 LEDs (total 5W)

4 normally-closed solenoids. (2W each)

Would i be right in saying that , instead of using one 54W Power Factor Corrected offline SMPS, we can simply use.........

one 40W (non-PFC) offline SMPS for the stepper motors

and

one (non-PFC) 13W offline SMPS for the solenoids and LEDs.

New laws mean PFC is essential for loads above 50W, but can we avoid PFC converters by simply splitting our loads up into 2 loads, each less than 50W?

We are currently designing an offline Power Factor Corrected Flyback for 53W of maximum output power.

This is for a temperature controlled , two outlet shower (head and body jets). The hot and cold water flow is controller by stepper motor valves.

(total 4 stepper motors).

Everything on the secondary side is an isolated load.

The loads are:

4 stepper motors (10W each)

80 LEDs (total 5W)

4 normally-closed solenoids. (2W each)

Would i be right in saying that , instead of using one 54W Power Factor Corrected offline SMPS, we can simply use.........

one 40W (non-PFC) offline SMPS for the stepper motors

and

one (non-PFC) 13W offline SMPS for the solenoids and LEDs.

New laws mean PFC is essential for loads above 50W, but can we avoid PFC converters by simply splitting our loads up into 2 loads, each less than 50W?