ElecDesigner

Member level 5

I am working on an application (reverse voltage swing on HV capacitors due to extremely rapid discharge) where diodes need to be able to handle currents of about 10kA for 100us or so.

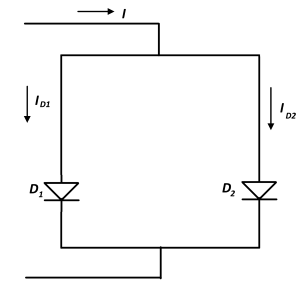

It might turn out to be space (and cost) efficient to use multiple devices in parallel to achieve the requirement. I am a bit skeptical about paralleling but it appears that it can be done, see:

Are there any additional pitfalls due to my application being a very short high current pulse. It is common to see inductors used to force leading edge sharing in Thyristors but I assume these are not needed for diodes as I assume the same dI/dt limits do not apply.

It might turn out to be space (and cost) efficient to use multiple devices in parallel to achieve the requirement. I am a bit skeptical about paralleling but it appears that it can be done, see:

Are there any additional pitfalls due to my application being a very short high current pulse. It is common to see inductors used to force leading edge sharing in Thyristors but I assume these are not needed for diodes as I assume the same dI/dt limits do not apply.