Enzy

Advanced Member level 1

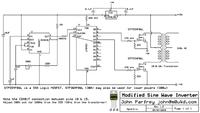

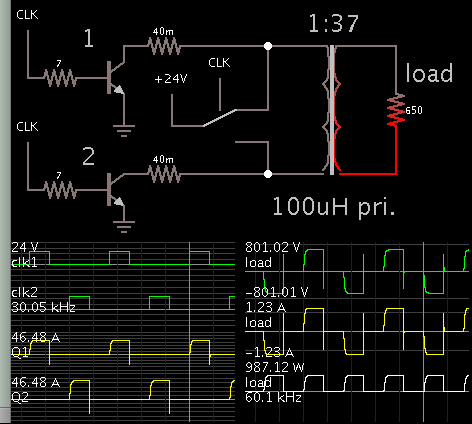

I wanted to build a circuit that can use 24vdc and converter to Ac @800v at about 60khz any wave form is acceptable, I was wonderin if anyone knew of any working circuits I could try out in a similar range.