1.5kV

Newbie level 4

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

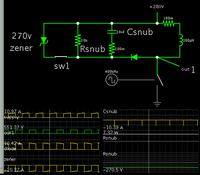

1. Is probably not likely to happen because capacitor can't charge to higher than 200V +/- tolerance because of clamp diode VR1. Only if clamp diode would react too slow when the voltage goes above breakdown voltage...

So far I haven't measured the leakage inductance yet - I know, that would be the first thing that i should do

BradtheRad I am not sure if I understand you correctly. If there would be current flowing thru the zener VR1 and D1 then the zener would be destroyed before D1. Power on zener is 200V*current, power on D1 is 0,7V*same current. Probably I didn't understand correctly.

Is C1 22 µF? How long are it's terminal wires.

Can you be more specific about the Line/Load conditions under which the circuit fails? Does D1 gradually heat up before failing, or is does it die immediately when those conditions are applied, regardless of temperature? This would help narrow down whether the issue is excessive conduction current or reverse voltage (or both).

The BYV26C is notorious for breaking down (from over heat) under high frequency hard reverse recovery (380V in this case) - if you put a thermo-couple on it and start the converter you will see its temp go up until it fails - chose a better diode with <35nS reverse recovery..!