Error_Amplifier

Junior Member level 1

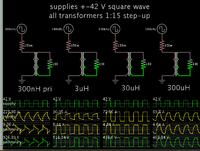

42 volt input from a battery source and 500 volt DC output is required. The switching frequency is 100 kHz. Full bridge with mosfets on the primary side and full bridge diode rectifier on the secondary side.

Please provide help for the transformer design and the feedback control implementation.

Please provide help for the transformer design and the feedback control implementation.