salah_edu

Junior Member level 1

Hi All;

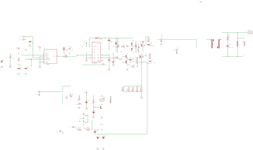

i have designed a 100 A stick welder using two switch forward converter topology , i used a switching transformer from an old igbt inverter welder , my problem is that the standby current is too high and the igbts are too hot, i tried to increase the switching frequency from 70khz to 140khz but the idle current is still too high, i tried also to reduce the gate resistor to reduce the switching loss but there is no improvement in igbts temperature , the current sensing resistor are five 100 mohm in paralelle connected to the low side switch in primary current.

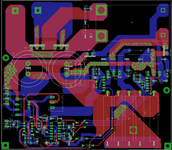

you find below the schematic and the pcb.

can you please help me to investigate this problem?

another question does a transformer need a target frequency to reduce the primary idle current?

i have designed a 100 A stick welder using two switch forward converter topology , i used a switching transformer from an old igbt inverter welder , my problem is that the standby current is too high and the igbts are too hot, i tried to increase the switching frequency from 70khz to 140khz but the idle current is still too high, i tried also to reduce the gate resistor to reduce the switching loss but there is no improvement in igbts temperature , the current sensing resistor are five 100 mohm in paralelle connected to the low side switch in primary current.

you find below the schematic and the pcb.

can you please help me to investigate this problem?

another question does a transformer need a target frequency to reduce the primary idle current?