bobsun

Full Member level 2

Hello,

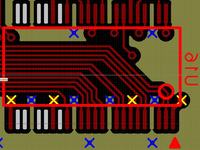

I would like to ask a question on symmetric component orientation.

Most of the components are symmetric at least in one dimension, and most chips are square. For things like this, how can we ensure that they will be soldered in the correct orientation, when they are not soldered by machines out of tape and reel, but in prototyping by manual soldering?

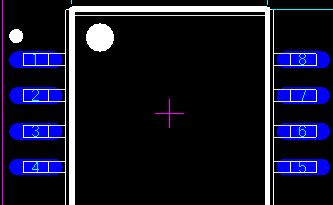

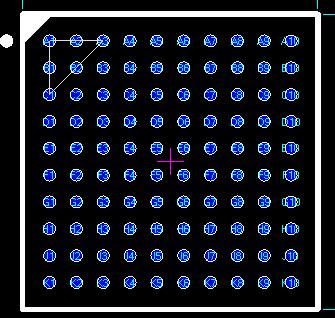

For example, the attached picture show a component whose pin arrangement is:

1 6

2 5

3 4

But after rotating \[{180}^{o}\] , they become

4 3

5 2

6 1

And if soldered in this way it will surely cause the system to disfunction.

So how could I prevent this from happening? Do I have to stand beside the solder worker and checking with component’s orientation from my laptop, and point out the right orientation?

Bob

I would like to ask a question on symmetric component orientation.

Most of the components are symmetric at least in one dimension, and most chips are square. For things like this, how can we ensure that they will be soldered in the correct orientation, when they are not soldered by machines out of tape and reel, but in prototyping by manual soldering?

For example, the attached picture show a component whose pin arrangement is:

1 6

2 5

3 4

But after rotating \[{180}^{o}\] , they become

4 3

5 2

6 1

And if soldered in this way it will surely cause the system to disfunction.

So how could I prevent this from happening? Do I have to stand beside the solder worker and checking with component’s orientation from my laptop, and point out the right orientation?

Bob