neazoi

Advanced Member level 6

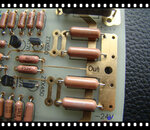

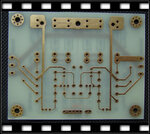

Hi, I am looking for PCB manufacturers, preferably in Europe but not only, that can do limited quantity orders (relatively cheap for hobby projects) and they are able to produce this kind of PCB attached.

If you see the PCBs attached, these are thick gold plated.

Also, the FR4 is bare (not painted with any mask) and it's color is mainly white with greenish-blueish color. Not the common yellow color found elsewhere.

These are the characteristics I am looking.

Anyone knowing such a manufacturer please reply here.

If you see the PCBs attached, these are thick gold plated.

Also, the FR4 is bare (not painted with any mask) and it's color is mainly white with greenish-blueish color. Not the common yellow color found elsewhere.

These are the characteristics I am looking.

Anyone knowing such a manufacturer please reply here.