masterx81

Member level 1

Is better for the lower Rdson, but i still have a lot of unanswered questions and doubts....

1) why they put a so high negative bias?

2) why the gate trace with drain disconnected has not shown the ringing present in the lowside trace with transformers connected?

3) why the isolation trasformer pass DC and the output waveform is so similar to input waveform?

Sorry, may seem stupid questions, but i really like to learn.... Really thanks...

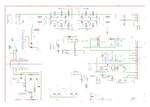

Another section of the welder:

On the top board there what seem to me a suppression circuit for protect the mosfet from overshot of the inverter circuit.

1) why they put a so high negative bias?

2) why the gate trace with drain disconnected has not shown the ringing present in the lowside trace with transformers connected?

3) why the isolation trasformer pass DC and the output waveform is so similar to input waveform?

Sorry, may seem stupid questions, but i really like to learn.... Really thanks...

Another section of the welder:

On the top board there what seem to me a suppression circuit for protect the mosfet from overshot of the inverter circuit.