umery2k75

Advanced Member level 1

speed control of dc motor using scr

Hi,

I'm developing Motor Speed Controller for Permanent Magnet Synchronous Motor(PMSM).I don't know why people love PWM so much for controlling the speed of the DC/AC motor.Every where I see is the PWM method for speed control, mostly in H-bridge manner equiped with transistors.I have my university final year project that is SCR based DC motor(1-phase) speed control in closed loop.So I'm desiging this project and I'm controlling the speed by the varying the firing angle of SCRs.The motor drive which I'm developing is AC-DC, that is it takes the Alternating Current to get Power.This motor operates in the 1st quadrant where both Voltage and Current is positive

Any comments,suggestions and view points will be highly appreciated

I bought this Permanent Magnet Synchronous Motor:

=======================================

D.C Motor 5 Horse Power

240 V, 16A, 2050 RPM

Single Phase

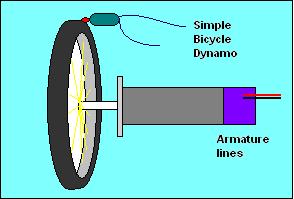

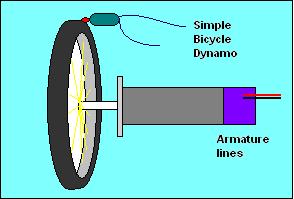

I am using 8051 microcontroller at this time for controlling the speed of the motor and this motor only has armature control.The speed will be set by entering the RPM through Keypad and speed would be control by Proportional Intergral controller, I will develop PI algorithm in the code, so I don't need to make extra analog circuit for this and I will have the LCD for the output of LCD and for feedback I am using bicycle dynamo for the feedback( I'm using this as RPM to Voltage converter-> the higher the wheel spins, it's corresponding voltage would be generated, so I can know with what speed the wheel is spinning).My circuit has zero cross detection circuit, I'll connect this output with interrupt of the 8051 controller, as soon as the (AC sine wave) 0 Voltage is reached, I'll come to know about the position of the sine wave and then fire the corresponding SCRs from 0-180 degrees ranging depending on speed required.

This tire will also contains the braking mechanism, as soon as I apply the brake the controller would sense the increasing of load and will reduce the firing delay for SCRs to generate more power to keep the wheel spining at constant speed in NO-LOAD to FULL-LOAD region.

The initial circuit which I have designed is this, I didn't get the time to make the proper schematic, I'll replace them as soon as I can.

That's the initial design

Feedback portion

The bicycle dyamo voltage is feed into ADC by which controller can sense the speed of the spinning tire.

It's power circuitry

I am also thinking of replacing the optoisolators with the pulse transformer as a better substitute( I don't know whether I'm correct or not) and to add the snubber circuit in paralled to Silicon Control Rectifier and Diodes for protection.My friend advised me to first design this circuit by using the smaller DC motor like 12V, because there is less likelihood for destroying the SCR's while making the circuit, because of high voltage/current and back emf.Once the coding for microcontroller is done and other necessary things, just simply replace the motor and few components with higher Voltage/Current ratings.

So I bought another small DC motor 12V and some BT151 SCRs which has current rating of 10A.

For 220V DC motor 5 HP, BT152 SCR will be suitable which has current rating of 15-20A as my motor need 16A.

Hi,

I'm developing Motor Speed Controller for Permanent Magnet Synchronous Motor(PMSM).I don't know why people love PWM so much for controlling the speed of the DC/AC motor.Every where I see is the PWM method for speed control, mostly in H-bridge manner equiped with transistors.I have my university final year project that is SCR based DC motor(1-phase) speed control in closed loop.So I'm desiging this project and I'm controlling the speed by the varying the firing angle of SCRs.The motor drive which I'm developing is AC-DC, that is it takes the Alternating Current to get Power.This motor operates in the 1st quadrant where both Voltage and Current is positive

Any comments,suggestions and view points will be highly appreciated

I bought this Permanent Magnet Synchronous Motor:

=======================================

D.C Motor 5 Horse Power

240 V, 16A, 2050 RPM

Single Phase

I am using 8051 microcontroller at this time for controlling the speed of the motor and this motor only has armature control.The speed will be set by entering the RPM through Keypad and speed would be control by Proportional Intergral controller, I will develop PI algorithm in the code, so I don't need to make extra analog circuit for this and I will have the LCD for the output of LCD and for feedback I am using bicycle dynamo for the feedback( I'm using this as RPM to Voltage converter-> the higher the wheel spins, it's corresponding voltage would be generated, so I can know with what speed the wheel is spinning).My circuit has zero cross detection circuit, I'll connect this output with interrupt of the 8051 controller, as soon as the (AC sine wave) 0 Voltage is reached, I'll come to know about the position of the sine wave and then fire the corresponding SCRs from 0-180 degrees ranging depending on speed required.

This tire will also contains the braking mechanism, as soon as I apply the brake the controller would sense the increasing of load and will reduce the firing delay for SCRs to generate more power to keep the wheel spining at constant speed in NO-LOAD to FULL-LOAD region.

The initial circuit which I have designed is this, I didn't get the time to make the proper schematic, I'll replace them as soon as I can.

That's the initial design

Feedback portion

The bicycle dyamo voltage is feed into ADC by which controller can sense the speed of the spinning tire.

It's power circuitry

I am also thinking of replacing the optoisolators with the pulse transformer as a better substitute( I don't know whether I'm correct or not) and to add the snubber circuit in paralled to Silicon Control Rectifier and Diodes for protection.My friend advised me to first design this circuit by using the smaller DC motor like 12V, because there is less likelihood for destroying the SCR's while making the circuit, because of high voltage/current and back emf.Once the coding for microcontroller is done and other necessary things, just simply replace the motor and few components with higher Voltage/Current ratings.

So I bought another small DC motor 12V and some BT151 SCRs which has current rating of 10A.

For 220V DC motor 5 HP, BT152 SCR will be suitable which has current rating of 15-20A as my motor need 16A.