Back in the early 1990's, I accompanied our chief engineer to visit Intel. My company had just designed a new high-density pin grid array socket for Intel's new Pentium family. The Intel engineers loved our product and used it in their laboratories for testing. But later during that visit, the Intel engineers told us: your product works great, we use it here in our labs, but we will never use a screw machine low-insertion force pin grid array socket in a consumer computer product. They continued, we will always use zero insertion force pin grid array sockets. They did not challenge the fact that our screw machine socket made a superior electrical connection. Their argument was simply -

consumers are not lab engineers and the risk of accidental damage was too great.. So the ZIF socket was the winner and exclusively used in early consumer computers.

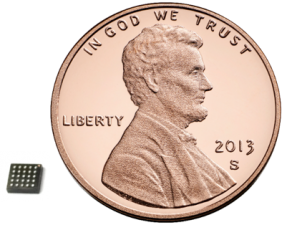

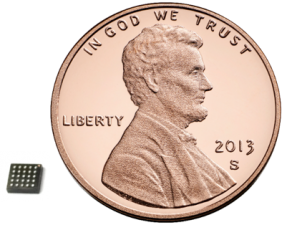

At some point semiconductor manufacturers realized that if they could eliminate the need for a socket and attach directly to the PCB, they could make faster circuits and eliminate a lot of associated costs related to connector hardware. As well as reduce the device profile. The Ball Grid Array is a packaging method using tiny spherical solder balls instead of pin leads. If there are no pin leads, then there's no need for a socket and the part can be placed directly upon the PCB.

Eliminating the socket reduces product assembly costs.

The PGA socket in both screw machine and stamped ZIF socket forms have for the most part become a thing of the past.

Fast forward 30 years....

Super fast signal speeds require finely tuned and calibrated circuits. Trying to pass high-speed signals through connector hardware is problematic. Typically requiring lots of shielding, strip-line construction, matching impedance, identical profile et.... The more bells and whistles required by the connector, the more expensive it becomes to manufacture.

Some very talented engineers discovered ways to eliminate connector hardware and pass high-speed signals as well as

power recharging through wireless methods.

Keyssa - high-speed wireless signal transfer (see link below)

www.linkedin.com

www.linkedin.com

Nucurrent - wireless power recharging (see link below)

These technologies although in their early stages of development will slowly replace a large

market share of the interconnect hardware market.

consumers are not lab engineers and the risk of accidental damage was too great.. So the ZIF socket was the winner and exclusively used in early consumer computers.

At some point semiconductor manufacturers realized that if they could eliminate the need for a socket and attach directly to the PCB, they could make faster circuits and eliminate a lot of associated costs related to connector hardware. As well as reduce the device profile. The Ball Grid Array is a packaging method using tiny spherical solder balls instead of pin leads. If there are no pin leads, then there's no need for a socket and the part can be placed directly upon the PCB.

Eliminating the socket reduces product assembly costs.

The PGA socket in both screw machine and stamped ZIF socket forms have for the most part become a thing of the past.

Fast forward 30 years....

Super fast signal speeds require finely tuned and calibrated circuits. Trying to pass high-speed signals through connector hardware is problematic. Typically requiring lots of shielding, strip-line construction, matching impedance, identical profile et.... The more bells and whistles required by the connector, the more expensive it becomes to manufacture.

Some very talented engineers discovered ways to eliminate connector hardware and pass high-speed signals as well as

power recharging through wireless methods.

Keyssa - high-speed wireless signal transfer (see link below)

Keyssa posted on LinkedIn

What is a wireless connector? See Keyssa's answer in an interview with Ken Werner in Display Daily: https://bit.ly/2Uej40B #wireless #connectors #60GHz...

Nucurrent - wireless power recharging (see link below)

These technologies although in their early stages of development will slowly replace a large

market share of the interconnect hardware market.