tiwari.sachin

Full Member level 6

- Joined

- Aug 1, 2009

- Messages

- 341

- Helped

- 3

- Reputation

- 6

- Reaction score

- 3

- Trophy points

- 1,298

- Location

- India

- Activity points

- 4,449

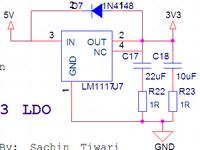

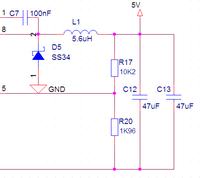

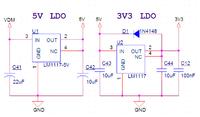

I am using 7.4V Li Ion Battery, followed by a 5V (1117) regulator, the output of which is given to 1117 (3.3V)

The input (Li Ion) voltage depending on load is flatuating (Dropping to say 6.8V).

I am connecting a bluetooth module also at 3.3V.

Observations

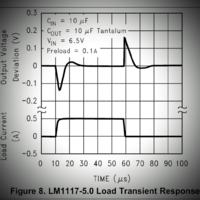

I closely looked and I saw that 3.3V drops 200-300mV (Approx) for about 7ms and comes back to 3.3V and some spikes (lots of up down lines on CRO) of few mV variations.

This I think is efefcting bluetooth throughput

How can i make sure that the voltage is stable

If I use a saparate supply only for bluetooth with common ground ofcourse, it works fine

The input (Li Ion) voltage depending on load is flatuating (Dropping to say 6.8V).

I am connecting a bluetooth module also at 3.3V.

Observations

I closely looked and I saw that 3.3V drops 200-300mV (Approx) for about 7ms and comes back to 3.3V and some spikes (lots of up down lines on CRO) of few mV variations.

This I think is efefcting bluetooth throughput

How can i make sure that the voltage is stable

If I use a saparate supply only for bluetooth with common ground ofcourse, it works fine