Vermes

Advanced Member level 4

- Joined

- Aug 2, 2011

- Messages

- 1,163

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,316

- Activity points

- 22,318

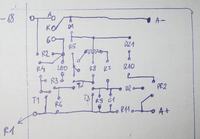

Elements used:

- transformer 150VA 230/18V

- bridge 25A 1000V

- resistors: R1 0,69ohm 50W; R1' 2,2ohm 50W

- fuses: on the transformer supply 230V 5A; at the output to accumulator 230V 10A

Thyristor BT151 on heat sink screwed to the housing heats up to 40 degrees Celsius. Rectifier bridge heats more, it is hot. Resistors R1 and R1' can act as heaters in winter. 50W were applied, because 10W heat up until they crash. The heating with screwed resistors does not heat up more than 70 degrees Celsius at long-term maximum current (6,5A).

The first switch on the left enables the supply for the transformer, the second one enables the resistor R1 and the third – R1' (resistors R1 and R1' can work in parallel).

Cables of both high-current circuits have the diameter of 2,5mm2 except those coming out of the accumulator, which due to their length of 3m have the diameter of 4mm2.

The housing was taken from a broken Einhell rectifier. It is connected directly with PE cable (device in protection class I).

Transformer originally was supplying halogen lighting on 11,5V, additional 31 coils were winded, and the whole protected using bandage soaked with epoxy resin.

Any surfces in contact, through which flows the heat, were put together on silicone thermal conductive paste. The construction is to work outside and in the garage, so it should be protected against moisture by painting the board with electro-insulating lacquer and use of heat-shrinkable tubing.

Pictures:

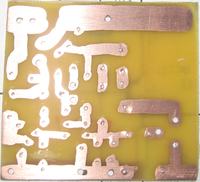

And the board:

Original housing with things taken out of it:

Link to original thread (useful attachment) – Automatyczny prostownik do ładowania akumulatorów 6A