Vermes

Advanced Member level 4

- Joined

- Aug 2, 2011

- Messages

- 1,163

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,316

- Activity points

- 22,318

The idea was to create an amateur hobby brushless motor.

Brushless motor

Brushless motor for the Piccolo by Hennig. LINK.

This is the engine removed from the ASUS CDROM drive (1999). This is a disc drive motor. Such motors have axle with the diameter of 3mm. Motors from 36x drives no older than 1999 should be used. The engine is not strong enough, so it should be modified a little.

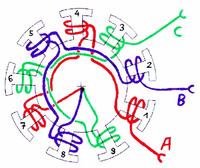

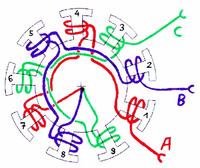

9-pole stator with windings and the winding direction. You must remove the old windings, then wind new ones. These will be three windings of 16 turns of top roll copper wire in enamel with the diameter of 0,4mm. The illustration shows how to wind the winding. Please note that all the windings are wound in the same direction and in the same way.

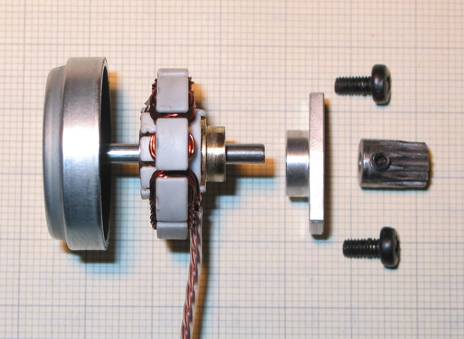

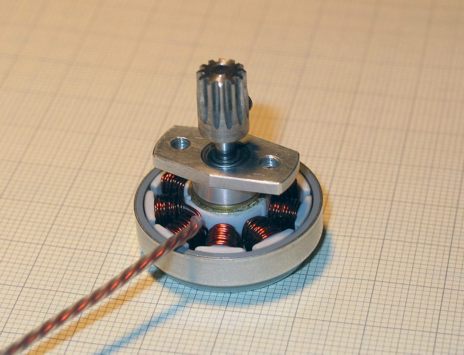

View of re-wound ASUSx40 engine in parts.

From the left:

- rotor with 12 field magnet

- stator with new windings

- handle with socket bearings and two M3 threaded holes

- ball bearing 2mm/5mm

- underneath the axle 3mm/2mm

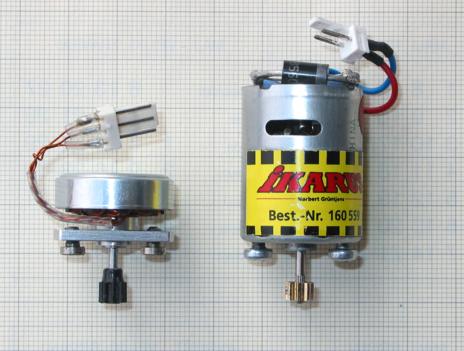

Here's comparison of the described engine with the original one for Piccolo Ikarus G-310. Both engines have similar power (efficiency). Clearly different dimensions.

Weight of Asus CDR-40x: 18g

Ikarus G-310: 49g

Engine mounted to Piccolo. Be careful with the cables. Engine rotating parts are uncovered. The regulator used was JETI 06-3P.

Here is the engine of similar design from CDROMx36 drive. Be careful with the insulation of the stator, it is very thin and delicate. It would be better to replace it with another, such as paper which is in wound capacitors.

In this case, three windings with DNE wire 0,4mm, 14 turns each were wound. The engine is used to slowflyer.

The same engine mounted.

Another way to get materials to build your own brushless motor is to dismantle the old hard drive of a computer. The disk may be damaged, just plates drive motor is important. Suitable are engines from disks 3,5” or 2,5” with a capacity of at least 200MB. Capacity is not important, but the engine itself. In older drives (20, 40, 80, MB) engines with 4 or 6 pole pairs were used. For our purposes, we need a motor with 9 or 12 pole pairs. Another selection criterion is the weight of the engine.

Dismantle the hard drive to remove the engine. To do this, unscrew the plated and heads. NOTE: the magnet in the heads drive engine is very strong. Rest is useless for our purposes. The only things ever useful are the bearings on which the heads arm is mounted.

It should be done carefully in order not to kill any bearing seat, not wince the axle. In these picture there is drive 2,5”, but it looks like 3,5”. Unfortunately, the 2,5 inch disks the bearing seat is also the body of the disk. So cut the right shape from the body, which will give the mount.

In this picture there is engine of 3,5” disk. It is larger and has a separate body of the lower bearing.

The same engine dismantled.

To knock out the axis from the bearing, take a solid hammer or welt. Axle up with the bearing should be heat up to about 150 degrees Celsius, because it is embedded in the adhesive. Without it, the bearing, stator or the axle would be destroyed. Then unfold the old windings and rewind new. For this, use wire DNE 0,4-0,5. Wind the 14-16 turns, remembering the same direction and order or winding the coils.

Link to original thread (useful attachment) – Silnik bezszczotkowy z CD-ROM lub HDD jako silnik modelarski