Vermes

Advanced Member level 4

The typical professional smoke generators are expensive and quite inefficient. Their average consumption is about 25ml per minute.

Assumptions of the solution:

- cheap

- efficient

- self made

In order to make the smoke generator as efficient as it's possible, tests were made. After injecting glycerine and distilled water (1:1) with a syringe straight to the stove, the generator was giving smoke only while injecting. After purging the stove with air, it turned out, that the generator makes a satisfactory amount of smoke without the need to add new portion of liquid and it lasts for about one minute. After first tests with a liquid pump and air pump it turned out that the generator using about 2ml of liquid makes smoke for about half a minute and the amount of smoke is really big.

The housing

Because of the high temperature, the housing has to be made of metal. It can be taken from an old VHS player. It was bent in two spots with a ruler by scratching few times with a flat screwdriver along the line. Then it bends on the cut line. The front and back panel was made of a cooker hood. Additionally, the circle visible on front panel is a lacquered ceramic board, used to prevent the stove from heating up the housing too much, but isolating the metal housing from the hot stove.

The stove

The heater was placed in an aluminum block and a copper pipe on one side. On the other side there was placed something similar to a coupler, what makes an ideal nozzle of about 2mm. The end of the nozzle is inserted into a hole drilled in the ceramic board. That's why the housing isn't heating up and the generator makes smoke with a proper pressure. The stove was mounted on a piece of ceramic board in order not to heat up the housing. The housing temperature is kept lukewarm.

The liquid pump

It's an ordinary washer pump from Audi/VW.

The air pump

It's an aquarium air pump, easily available and cheap.

Controlling

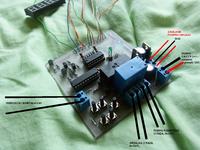

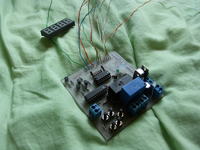

The whole control system had to be planned. The assumptions of the program were to control the air pump, liquid pump and the heater. The smoke was to be generated only when the bimetallic thermostat was obtuse. The bimetallic thermostats stop working properly after some time because of the tension and intensity coming through it, so the thermostat controls Attiny 2313 by 'mass release' into the processor's pin. In order to make the automatic control of the generator by the processor possible and easily make the smoke, a multiplexing control by 4-segments display has to be learned and a program to count the time has to be written.

One of the assumptions was to set the waiting time (minutes – max 99 minutes) and the liquid administering time (seconds – max 99 seconds). The start/stop button is used to do that. Two segments are the waiting time, the third and fourth segment are the liquid administering time. If on the display is set e.g. 0203, that means, the liquid would be administered every 2 minutes and it would last for 3 seconds.

Automatically, with every smoking, the air pump is powered on. It works for one minute and blows out all the smoke from the stove chamber. Then the liquid isn't administered anymore.

Whether the stove is heated up or not, one diode (green-red) shows it's state. Two red diodes signalize the pump work.

Four buttons are to set the time. One button start/stop starts or stops the program work. Two buttons are to control the smoke generator by hand. One of them is the liquid pump, the other is the air pump.

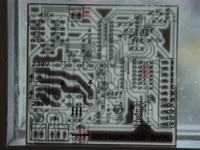

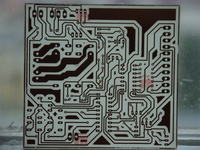

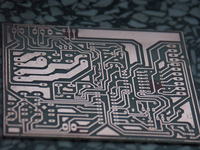

The board was made in thermal transfer method. Transmitters control the heater and the air pump. The liquid pump is controlled by a Mosfet transistor.

The whole device is controlled by Attiny2313. The program is 99% filled. The accuracy of the clock is satisfying. About 10 minutes is perfectly counted. When an hour is counted, the accuracy decreases to about 2 seconds delay.

To prevent the overheating, a thermal fuse 230V 10A 280 degrees Celsius was used.

The most important is that it's possible to set any waiting and smoking time depending on our needs and the dimensions of the place.

The reservoir

The reservoir capacity is 250ml. The filler plug was made of a piece of tube-type container.

The other things

The below schema shows the links of hoses with air and liquid:

The inside is filled with standard mineral wool, e.g. URSA. At first it stinks, but after 4-5 heating times there's no smell.

The housing is grounded.

ATTENTION! During producing the smoke in this videos, the smoke generator used only 6ml!

The level of liquid was marked before producing the smoke. After making this two videos, only 6ml liquid was added to reach the marked level. This shows how efficient the generator is. It produces dense white smoke clouds.

Link to original thread – Wydajna wytwornica dymu własnej konstrukcji

Last edited: