gres

Full Member level 4

- Joined

- Nov 30, 2009

- Messages

- 210

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,296

- Activity points

- 4,573

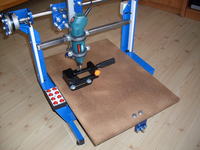

It’s a cheap, metal construction for working with soft materials. Next time I will use linear roller bearing. More expensive but much less work to do with them. There is only one hardened fence at each axle. In X axle table is set by two rolling bearings, that don’t change position in X axle. That makes great prop-up element . Y axle consist second fence made in 20x20profile. After had brushed, profile got nice metal color. Z axle consist second fence made up of aluminium profile. Typical bearings works with prifles. Backlash you can cancel by rag bearings situated on special arms. Feed screws I made from M6 rods. Incline 1mm/1 rotation. I used step engines 0,4Nm ( power increase to 0,6 by voltage). While testing, Z axle was able to move up all construction ( 12kg weight!) So power is enough. Screws works with nuts. Screws connected with engines by hose and pull up by bearings.

Frame construction – steel angle bars 50mm 45mm and wall 5 and 4mm.

Electronics is under the table. Signals amplifier is made on immortal ULN2803. This element is powered from PC, rest from milling power supply. Each engine consist own driver based on ATTINY2313 drive by 20MHz quartz. Executive transistors are IFR510. Standard steering – step, direction. 0/I switch connect milling machine with PC.

Power supply at second casing ( those with radiator) can give 11V without stabilization. Stabilizers powered each axle drive separately. Engines are powered by current source. It allow to better engine culture with smoothly worse power. With semi – step steering current is split to two cells.

Construction is really easy. All you need is driller, sander and welding machine.

More information at https://www.elektroda.pl/rtvforum/topic1540457.html